I received a lot of feedback from the article on EVs. Some thought I was opposed to EVs because of the issues I raised. That is not the truth. I think we must move towards EVs but we should do so with our eyes open. It is not all magic and kumbaya. There are implications, and if we are not aware of the problems the planet will be in a worse situation than using hydrocarbons. For this reason, I have taken a look at the metals that go into the batteries. This is part one.

As sales of electric vehicles escalate, what is the impact on producing the metals used in the batteries? The three main ones are Nickel, Cobalt and Lithium. All have been used for other purposes but now there is a surging demand for extra production of batteries. For example, the typical EV uses 60kg of Nickel.

Background of nickel

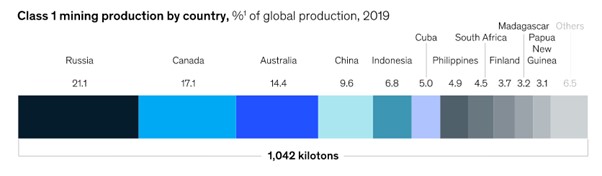

Nickel has mainly been used to produce stainless steel. The main producers are Russia, Canada and Australia. There are two types of Nickel. Class 1 and Class 2. To simplify the difference, think of the difference being the number of impurities. Stainless Steel can use a mix of Class 1 and Class 2 but for batteries, only Class 1 can be used.

Source: McKinsey & Co.

Types of Nickel

Types of nickel

There are two types of ore. One is sulphide and the other laterite. The mining of each is very different.

- Nickel from lateritic ore is mined at various depths beneath the surface using large earth-moving equipment. Basically, it is open-cut mining.

- The other nickel-containing type of ore, sulfidic ore, is usually found in combination with copper ore and is mined underground.

The lateritic ores of nickel occur in many areas of the tropics and sub-tropics. Major deposits being exploited are in Cuba, the Dominican Republic, Guatemala, Brazil, Australia, Philippines, Indonesia, New Caledonia, U.S.S.R., and Yugoslavia. Sulphide is mainly found in Canada, Australia, U.S.S.R., Republic of South Africa, Zimbabwe, and Botswana.

The extraction of sulphide has three main steps. Roasting, smelting, and converting. Without getting too technical, the purpose is to remove the sulphur from the ore. The main pollution concerns are solid waste, and the capture of the gasses. As you can imagine, some countries are better at controlling the hazards than others.

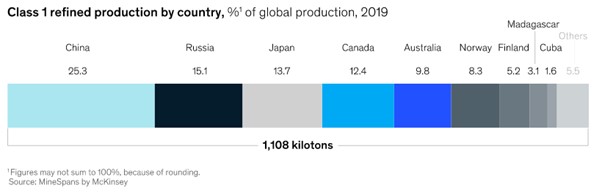

Extraction is only half the story. The other major part is refining. Refining nickel is a complex process compared with other metals. Copper refining is only one basic process. Lead and Zinc use a couple of basic processes. Nickel on the other hand uses many processes. There are a range of processes available, and refiners pick a combination in order to end up with the final product. The combination is determined by the impurities present, the cost and the environmental impact.

In terms of location, you can see by matching the production and refining charts that there is considerable shipping of the raw product from where it is mined to where it is refined.

Danger from mining

According to the UN, there are many hazards for workers. This is from a UN report on environmental concerns.

III. THE WORKING ENVIRONMENT AND ITS PROTECTION

111.1 General

Nickel production consists of several sequential steps from mining, crushing, and milling to smelting and refining. During the later stages of nickel production, a worker may be exposed to various potential hazards associated with nickel and nickel compounds,

- sulphur dioxide,

- dust,

- carbon monoxide,

- hydrogen sulphide,

- arsenic and other heavy metals,

- polycyclic aromatic hydrocarbons (PAH), and

- physical stresses such as heat and noise.

The ore usually contains a high sulphur content which ends up as either SO2 gas or sulphuric acid. If sulphur dioxide escapes, it can form acid rain. Nickel contact can cause a variety of side effects on human health, such as allergy, cardiovascular and kidney diseases, lung fibrosis, lung and nasal cancer.

Russian company Norilsk Nickel has managed to make their hometown Norilsk one of the most polluted in the world. They release 350,000 tonnes of sulphur dioxide annually. Norilsk is about 200 km from the Arctic Circle

In 2022 in Indonesia nickel mining caused red seas and no fish in the area. A summary of a report stated:

- Fishermen in Indonesia’s Obi Islands blame the nickel mining and smelting industries for the depletion of fish in their traditional fishing grounds.

- Researchers say the pollution has turned the coastal waters into a “mud puddle” because of the high levels of heavy metal contamination.

- One of the main mining companies there had previously proposed dumping 6 million tons of waste a year into the sea but backed down following protests.

- The company is now proposing clearing a forest area to build a tailings dam — a plan that activists and fishermen say is no better because of the persistently high risk of environmental contamination.

Source: Mongabay Series Feb 22

In 2020 they had a diesel spill that was about half the size of the Exon Valdez spill. The spill of 6.5 million gallons polluted rivers, forests and lakes and although it was denied that it reached the Arctic waters, traces have been found by the Russian government’s fisheries science agency.

What should be noted is that it was not the nickel that caused the problem of pollution, It is the infrastructure of the mine which caused the issue. Any mining in such a remote and environmentally sensitive region has its risks. It could have been nickel, it could have been gold, it could have been oil. If you undertake such activities in a particularly environmentally sensitive area, it is only a matter of time before something goes wrong.

In Indonesia, 17 mines were closed in 2017 due to environmental concerns.

The future

So, what does the future hold? In 2021, to meet the demands of stainless-steel production and batteries for EVs, an estimated total of 2.7 million metric tons of nickel was produced in mines worldwide. That is forecast to rise to 3.9 million metric tons by 2030 according to the Minerals Council of Australia. We are expecting a growth of 44%. Mining giant Vale, which is the biggest minors of nickel, estimates that between now and 2030 we will see demand increase by the same figure – 44%.

This requires world-wide mining to increase by about half in 8 years. Australia has about a quarter of the known nickel reserves and 10 mines. There will be an enormous cost involved in setting up new mines and refining facilities. Perhaps those opposed to any mining can explain how the nickel will be provided for those electric cars they are so keen for us to have if not from new mines. Shortages are also forecast and prices will increase simply through supply and demand pressures.

The latest developments

But wait. There is another solution. At the bottom of the ocean are nodules that contain nickel. They are 1500 to 2000m below sea level. They have been known for many years, but it was too expensive to mine them.

Many decades ago the UN set up an agency to ensure that developing countries had access to minerals on the seabed. Since its inception in 1982, the International Seabed Authority (ISA), charged with regulating human activities on the deep-sea floor beyond the continental shelf, has issued 27 contracts for mineral exploration, encompassing a combined area of more than 1.4 million km2, and continues to develop rules for commercial mining.

One leading contender is The Metals Company. It is a Canadian company headed up by an Australian. They are currently exploring an area between Hawaii and South America and trialling extraction techniques. This is a description of the process they will use.

When operational, a full-size treaded vehicle is expected to travel across the sea floor blasting the sediment with water jets to dislodge the nodules and pull them into its interior. The company says 90 per cent of the sediment sucked up with the nodules will be separated inside the collector and ejected behind the machine in a plume before settling back onto the sea floor.

From there, nodules will be sent up the riser tubes to within a few hundred metres of the surface, where they’ll be scrubbed of the remaining sediment, shipped to a port and offloaded for processing.

Source: Stefan Labbé – Business in Vancouver | July 5, 2022|

What could possibly go wrong? Travel across the ocean floor blasting the bottom with a water jet and sifting out rocks in a scoop. Drag it up halfway and give it a scrub. The ocean bottom probably needs a bit of a clean at that depth. Of course, no crabs will be hurt in the process.

Summary

In summary, with nickel, we have a surging demand over the next few years for a metal that is both scarce and complex to mine. It causes significant pollution of both sulphur dioxide and sulphuric acid. There are not enough mines and it is likely we will have shortages causing price increases. Steps are underway to mine from the ocean floor but the environmental impacts do not seem to be on the mainstream radar at present. Perhaps petroleum is not that bad.