Prefabricated Housing

Prefabricated Houses

Some friends bought a house many decades ago. Not your average purchase, it was cut in half and moved to a new location. There it sat on preprepared footings, and they have lived in and expanded it over the years.

The cost of building and the time taken have expanded enormously over the last decade. One limitation of building a house is the shortage of labour. There are just not enough trained builders, electricians, plumbers, and other skilled workers. It got me thinking about how we could build both faster and more cheaply. Since a house consists of materials, labour and a place to build it, how can the cost be reduced and the completion brought forward? How can unexpected delays from weather, which cause a domino effect on scheduling, be avoided?

Once, cars were handmade, then Henry Ford came along. The production line slashed the cost of a car. Can we do the same with houses?

It is probably worth defining “prefabricated housing”. Broadly speaking, it is any building system in which primary components are manufactured off-site and then transported for assembly. Into this category we have long included frames and trusses. These are the wooden wall and roof frames manufactured in a factory rather than built on-site.

Today, prefab includes everything from simple kit homes to high-end modular architecture and industrial-style container dwellings. Its growth reflects a combination of housing demand, labour constraints, sustainability goals and the appeal of faster, more predictable building processes.

A Brief History of Prefabrication in Australia

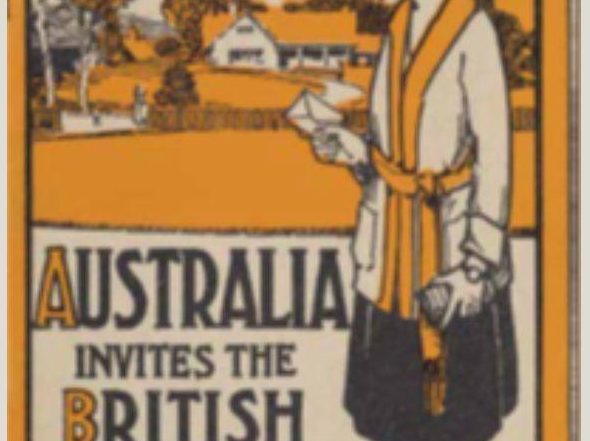

Australia’s relationship with prefabrication stretches back to the early colonial period. In the 19th century, prefabricated iron and timber cottages were imported from Britain to support rapid settlement in remote locations where skilled labour was scarce. These early examples demonstrated the advantages of factory-made components in a country with long supply lines and a dispersed population. It was exasipated by the gold rush where thousands of new residents needed something more than a tent.

After World War II, prefab saw renewed importance. Rapid population growth, a housing shortage, and a shortage of skilled trades led governments and private companies to explore factory-built housing systems. Timber-framed kit homes, transportable cottages and sectional buildings became common, particularly in regional and mining areas where on-site construction costs were high.

After World War II, prefab saw renewed importance. Rapid population growth, a housing shortage, and a shortage of skilled trades led governments and private companies to explore factory-built housing systems. Timber-framed kit homes, transportable cottages and sectional buildings became common, particularly in regional and mining areas where on-site construction costs were high.

Over the last two decades, the industry has evolved significantly. Advances in engineered timber, computer-aided design, modular systems and energy-efficient materials have positioned prefab as a modern, desirable alternative to traditional construction. Architects and developers increasingly use modular units to meet sustainability standards, shorten project timelines and reduce waste. Government agencies have also explored off-site construction to deliver social and regional housing more efficiently.

Types of Prefabricated Homes

Australia’s prefab sector is diverse, and the main categories include:

Kit Homes

Kit Homes

These are panelised systems where pre-cut or partially assembled components (walls, trusses, floors, cladding) are delivered to the site. Owners may hire a builder for assembly or, in some cases, undertake parts of the construction themselves. Kit homes appeal to those seeking cost control and flexibility in finish levels.

Modular Homes

Modular construction involves volumetric modules built in a factory, often complete with internal linings, cabinetry, plumbing and electrical wiring. Modules are transported to the site and craned into place, then joined to form a complete dwelling. Modular homes offer high consistency, rapid assembly and good cost predictability.

Modular construction involves volumetric modules built in a factory, often complete with internal linings, cabinetry, plumbing and electrical wiring. Modules are transported to the site and craned into place, then joined to form a complete dwelling. Modular homes offer high consistency, rapid assembly and good cost predictability.

I once watched a Grand Designs UK episode where a home was built in Germany and transported to the UK. The standard of finish would do credit to Mercedes or Audi. A team from Germany assembled the unit and returned one kitchen panel for remaking because the tiling was off by a few millimetres.

Panelised Building Systems

Panelised Building Systems

This includes SIPs (structural insulated panels), CLT (cross-laminated timber) panels and other factory-assembled wall and roof systems. Panels arrive ready to erect, reducing site labour and enabling excellent thermal performance.

Light-Gauge Steel Systems

Light-Gauge Steel Systems

Steel-framed homes are manufactured using precision machines to cut and assemble framing components. Steel is dimensionally stable, termite-resistant, and suited to modular and multi-storey designs. An added benefit is that it bolts together like a Meccano set.

Transportable and Relocatable Homes

Transportable and Relocatable Homes

These single-piece dwellings are built on a transportable chassis and delivered fully assembled or nearly complete. They are common in mining areas, rural communities, and as affordable secondary dwellings. They also form a large part of temporary school buildings.

Tiny Homes and Small Modular Units

A growing niche exists for compact prefabricated dwellings used as studios, granny flats, rentals and off-grid cabins.

Shipping Container Homes

An increasingly recognisable member of the prefab family is the shipping container home. These homes repurpose standard 20-foot or 40-foot steel shipping containers as building modules. Popularised through media and architectural experimentation, container homes appeal to people seeking a rugged, industrial appearance or modular flexibility.

An increasingly recognisable member of the prefab family is the shipping container home. These homes repurpose standard 20-foot or 40-foot steel shipping containers as building modules. Popularised through media and architectural experimentation, container homes appeal to people seeking a rugged, industrial appearance or modular flexibility.

Containers are taken to a workshop where builders cut openings for windows and doors, install insulation, add internal framing, and fit services such as plumbing and electrical systems. Modules can be used individually as studios or linked horizontally and vertically to create multi-container dwellings.

Containers have inherent structural strength, can be stacked for transportation, provide a use for containers at the end of their lifecycle and are quick to assemble.

Materials and Construction Approaches

Prefab construction in Australia uses a broad spectrum of materials:

- Timber framing: Lightweight, fast to produce, and suited to most climates.

- Engineered timber and CLT: Provide high strength, stability and excellent thermal performance.

- Light-gauge steel: Delivers precision, termite resistance and suitability for modular assembly.

- SIPs and insulated composite panels: Offer high energy efficiency and rapid construction.

- Precast concrete panels: Used for durability, thermal mass and multi-storey systems.

- Container-grade corten steel: Specific to container homes, often lined internally with timber or composite framing.

Site conditions, bushfire or cyclone ratings, acoustic needs, desired aesthetics and budget shape material choice.

Quality Control and Compliance

One of prefab’s major strengths is the ability to build in controlled factory environments. This reduces weather exposure, improves accuracy and allows rigorous quality checks before components reach the site. Many manufacturers adopt detailed QA systems, component barcode tracking, and repeatable production processes similar to those in manufacturing industries.

Regardless of building method, prefab homes must comply with the National Construction Code and relevant Australian Standards. Councils still assess planning requirements such as setbacks, height limits, bushfire overlays and flood considerations. While factory quality is high, on-site work — including footings, cranage, module connections, and service hook-ups — remains a critical step that affects overall durability and performance.

Cost Considerations

Costs vary substantially depending on the type of prefab system, the level of finish, transport distance and the complexity of site works. General patterns include:

- Kit homes: Often the most economical upfront, though final cost depends heavily on on-site labour, trades and finishing.

- Modular homes: Typically priced as near-turnkey packages with ranges that overlap mid-market conventionally built homes.

- Container homes: Base modules may appear cheap, but structural modifications, insulation upgrades, engineering, transport and compliance can raise the final cost significantly.

In all prefab systems, transport, cranage, foundations, site excavation, utility connections and council fees are significant variables. These costs may exceed buyers’ initial expectations if the site is steep, remote, or difficult to access.

While prefab is not universally cheaper, it offers substantial value where speed, predictability, reduced delays, and quality control are priorities. For regional builds in particular, it can dramatically reduce labour costs and project timelines.

Benefits of Prefabricated Construction

Prefab offers a range of practical advantages in Australia’s housing environment:

- Faster construction: Buildings can be completed in weeks instead of months because factory and site work can occur concurrently.

- Predictable schedules: Weather exposure is reduced, limiting delays.

- Higher quality consistency: Factory conditions support stricter tolerances and repeatable workmanship.

- Lower material waste: Offcuts are recycled more efficiently in controlled environments.

- Better sustainability potential: Many prefab systems incorporate energy-efficient materials and tighter thermal envelopes.

- Improved safety: Workers operate in safer, ergonomically managed environments compared to open building sites.

Conclusion

Prefabricated housing in Australia has evolved from colonial-era kit cottages to a diverse and sophisticated construction sector that includes modular homes, panelised systems, eco-engineered timber structures and industrially inspired container dwellings. While not always cheaper than conventional building, prefab excels in speed, quality control, reduced waste, and suitability for regional or complex sites.

Container homes, in particular, highlight the adaptability of prefab — blending reuse, modularity and some exotic design. When using prefabricated components, owners need to consider compliance, transport, craneage, and site costs.

As demand for efficient, sustainable and flexible housing grows, prefabrication is likely to evolve and play an increasingly important role in reducing labour costs and improving home construction quality.